We have entered the era of the fourth industrial revolution, where the scope of automation and significance of the same has reached its apex. The need of today is to introduce the people to these technologies which are in demand today, such as artificial intelligence, robotics, the Internet of Things, autonomous vehicles, 3-D printing, nanotechnology, biotechnology, materials science, energy storage, and quantum computing. But still, we are habitual of using conventional technologies, which is the topmost barrier in the company growth.

In most of the industries where there is the need for movement of objects, lifting of materials, or whether it’s handling of material, we still use manpower. But are we really aware of the weight capacity that one is liable to hold or lift?

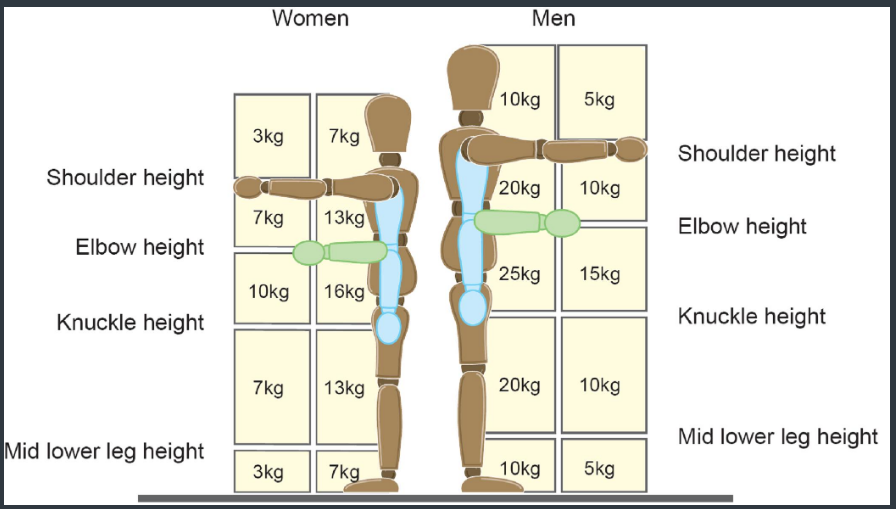

Here is a pictorial idea of how the weight should be handled and what the correct positions are to avoid physical disorders.

STANDARD MANUAL MATERIAL HANDLING WEIGHT CONSIDERATION

The guidelines suggest that the maximum weight men should lift at work is 25kg. This relates to loads held close to the body at around waist height. The recommended maximum weight is reduced to 5kg for loads being held at arm’s length or above the shoulder height. Maximum weight guidelines recommend lower weights for women.

HOW TO REDUCE THE CHANCES OF INJURIES DUE TO MANUAL HANDLING?

As every problem has a set of solutions. But defining the right solution to the problem depends on each individual. So here is the set of different solutions listed below.

- MOVE TOWARDS THE INNOVATION

This will fulfill your needs, considering the new technologies, Automation in industries. The use of automation in companies will make the company grow at a faster pace. Now, you can’t just ignore the competition around, and to excel among all, you have to move towards innovation. In order to remain competitive, businesses must ensure the timely and uninterrupted flow of raw materials and end products across the manufacturing process and supply chain, together with flexibility.

In food industries, frozen food products consist of fresh products, dough, various popular and special ingredients, as well as dairy products. In order to conduct these tasks quickly and without damaging any of the inventories, each element must be delivered to production lines on time and as and when necessary, indicating the need for proficient material handling equipment.

Right Conveyors and forklifts are used when filling heavy boxes or cartons of finished food goods to ensure that they are filled safely.

- CHOOSE THE RIGHT EQUIPMENT

Keeping in mind the company requirements, the materials to be handled, the time required for completing a particular task, the distance to be traveled, heights to be reached, the processes involved, and much more. Using the right machines, by automating the pickup and drop of products, it becomes easy to transport raw materials and finished products safely all over the factory.

- WORKER FRIENDLY ENVIRONMENT

When it comes to material handling workplace, the conditions there may be different. The working temperatures might be low or might be high, so proper equipment must be given to the workers. Workers should be given some break in between as the fatigue mitigates the decision power due to continuous lift. Tired workers are less attentive, so they should be reminded to drink fluids to keep their bodies hydrated and to keep themselves active.

The overall result of the above solutions will lead to a productivity increase, eliminating the waste, higher production in lower costs, and with full safety of workers. This ultimately leads to company growth.

We are actively working on improving the ways for making each industry a better workplace to work. We are continuously involved in helping the industries to reduce the risks of manual material handling by providing them a better solution for effortless material handling!!

Stay updated with the latest happenings in the industrial world; do SUBSCRIBE to our newsletter to get more insights.